Hawk multi-functional block machine is designed to meet the mass and stable production of a variety of blocks by changing the different moulds. This contains the production of bricks, pavers, hollow blocks, kerbstones etc. With humanized designed aviation plugs for connection and automatic control system, the machine is extremely easy to use for everybody.

Compact heavy machine frame of welded sectional steel construction; improved synchronized vibration system; Siemens motor; Yuken high-dynamic valves; Omron PLC-Electronics control system, all high quality parts and excellence manufacturing different Hawk machine with competitors.

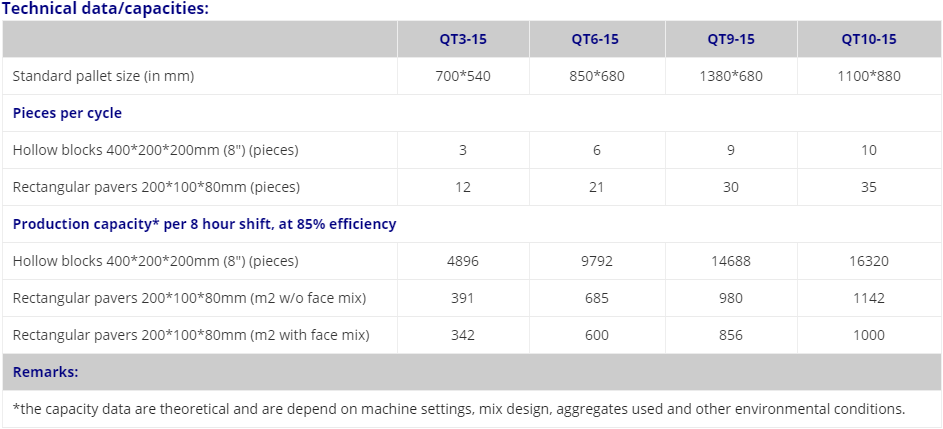

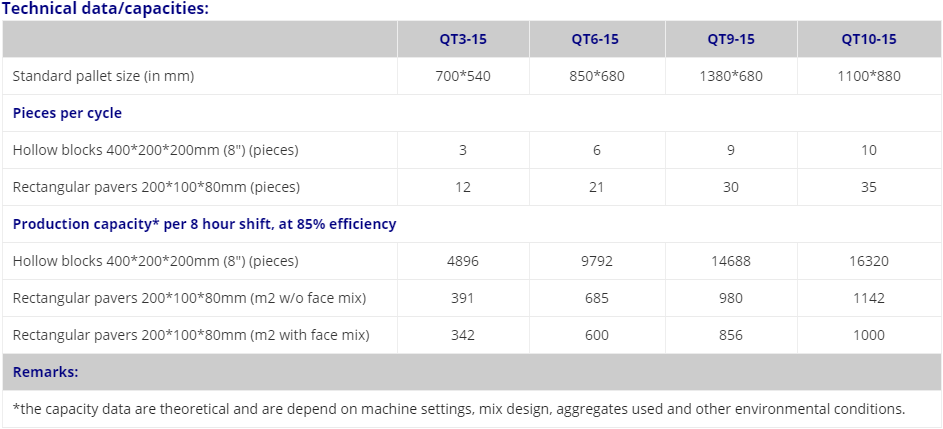

We have multiple model types machines with different capacity to match various requirement.

Machine Album

Aggregate Dosing and Concrete Mixing Plant

Quality from the very beginning - that is our philosophy. The use of comprehensive and effective

dosing systems

guarantee optimum and efficient delivery of raw inputs (for example, sand, cement, water, additives) to cement mixers.

Using the tried and tested Hawk concrete mixers results in reliable and high-quality mixing. Both the horizontal compulsory

mixers series "PH"

as well as the

Hawk mixer "S 350/500"

demonstrate highly desirable results with short mixing times and optimal material and energy inputs. Ease of maintenance and durability makes this Hawk concrete mixer a worthwhile long term investment.

Another important part of the manufacturing process is the individual color design of paving stones or other concrete stones. It can be achived in both simple and complex

multi-color systems

for main and face concrete.

More about Hawk Mixer

Concrete transport systems

Depending on the system layout, the Hawk concrete mixers are positioned directly over the concrete block machine or outside the plant. The transport of the concrete from the outside concrete mixing plant to block machine is most frequently by use of a bucket conveyor system although other systems can be utilized. According to customer requirements different bucket conveyer variations are available.

more

Concrete Block Making Machine

The heart of every concrete block making plant is undoubtedly the concrete block making machine. With the right choice. In the long run you can compete confidently in the market. The Hawk product range includes in the area of "vibration machines" powerful entry-level models of the

L-series

as well as comfortable heavy weight class models of the

XL-series

.

Here all Hawk models impress with a robust construction and the use of high quality materials. Hawk combines decades of experience with constant development - an unbeatable combination!

Offered especially for the production of concrete curbstones for "British Standard" with a purely hydraulic compression system, Hawk also offers

concrete curb presses

.

Wet side transport

The Hawk wet side transport ensures that the freshly-produced products are conveyed gently and without loss of quality from the block making machine to the elevator. At the same time Hawk does not lose sight of the importance of quality control.

As proven standard solution, Hawk offers a walking beam conveyer with servo drive, providing a low-vibration transport of fresh products. However, Hawk can also supply alternative transport systems.

Ahead of the actual conveying path is the lowering rocker which can also be used for doubling of production pallets. In the high speed S-package the lowering rocker is combined with a V-belt conveyor. It is synchronized with the production pallet feed of the block making machine.

Optionally further components can be installed on the wet side, for example:

Elevator

The transportation of fresh products into the curing area and the subsequent removal and transfer of the cured products require an intelligent integration of various system components.

The Hawk elevator collects production pallets with fresh products. Production pallets are cyclically transported upwards.

Once the elevator has reached a defined limit, production pallets are picked up by finger car and transported to one of the curing chambers.

Finger car

The finger car itself consists of a track-bound undercarriage (with or without turning device available, depending on plant layout) and an upper structure. After the finger car has accurately positioned in front of the curing chamber, low-vibration transfer into the curing chamber takes place. The stocking process of the products into the curing chamber takes place on a user prescribed basis.

After curing, the production pallets are again taken up by the finger car and either transported first to the intermediate finger car (optional) or directly to the lowerator.

Curing chamber and ventilation

To cure the products Hawk offers an innovative open-plan concept: The complete curing chamber as well as elevator, finger car and lowerator will be installed in a coherent climate area. The Hawk ventilation system can optimize the curing process by creating uniform climate conditions in the curing chamber.

It consists of horizontally arranged air-circulating fans in a separate air shaft, vertically arranged exhaust fans and diagonally arranged humidity and temperature sensors. By means of the sensors the circulated air is monitored, the circulating air and exhaust air fans are controlled accordingly.

Goals of regulation of the temperature and humidity in the curing chamber are the avoidance of color differences for uniform products, the realization of a faster curing and ultimately a more effective use of cement and color.

Intermediate finger car

The Hawk intermediate finger car precedes the lowerator, serves as a intermediate buffer and prevents waiting times of the finger car. It is one of the components utilized with the simultaneous use of a production pallet buffer in the cross transport area.

Lowerator

The Hawk lowerator is structural identically to the elevator, but unstacks the production pallets in a downward fashion and passes it to the return transport.

Hawk offers lifting / lowering devices, intermediate finger car and finger car for different plant layouts. Carrying capacity, numbers of floors and floor height are each suitably dimensioned. The entire process is fully automatic.

Return transport

In the area of the return transport Hawk uses completely electronically controlled drive systems.

The return transport is implemented as a servo-controlled walking beam conveyer. However, other transport systems are offered as well. Production pallets with the cured products transported from lowerator to the cuber or alternatively transported to the remodeling.

After taking off the products by the cubing device, the return transport also conveys the empty production pallets to the cross transport / production pallet buffer.

Optionally on the dry side also further components can be installed, for example:

- push together device for production pallets

- centering device and block doubler

- cleaning scrapers or cleaning brush depending on the production pallet type

- packaging systems for individual layers

Centering device

Hawk centering device is one of many components for realizing an optimum product handling. The cured blocks are loosed from the production pallet and centered. The centering is performed by a four-sided centering clamp both transversely to the transport direction and in the direction of transport.

Depending on the plant layout, the doubling of the stone layers is required. This can be realized by means of the Hawk doubler. The doubler is performed in a similar construction as the centering device, but equipped with a lifting device. The products are loosed and centered and the stone layers are doubled. Optionally, a horizontal turning device can be offered to rotate the stone layers individually.

Both the centering and the doubler drives are servo-controlled.

Production pallets - cross transport and buffer

After removal and cubing of finished stones by the Cuboter the empty production pallets are fed back into the production cycle. In order to enable two-sided use, production pallets are turned.

Depending on the plant layout either the transport pallets are transported continuously to the production pallet magazine of the concrete block making machine, or it follows the buffering or storage of the production pallets.

The balancing of different cycle times of the fresh and dry side as well as the pure outsourcing possibility of production pallets play a crucial role in the selection of the production pallet buffering.

Hawk offers different buffer systems, which for example, compensates (short) interruptions and guarantees a smooth production process by the concrete block machine.

more

Cubing

A high-quality concrete block requires sensitive handling. For this application Hawk offers fully servo controlled cubing systems: By means of the "Cuboter" Hawk delivers the technology and expertise to make the final product ready for shipment.

By means of the Cuboter it is possible to take a complete block layer from the return transport or from other take off positions and assemble it on the subsequent cube transport to a stone cube. Transport pallets and packing systems can be used individually.

more

Cube conveyor

After the cubing follows the cube transport: Hawk generally uses a robust double chain conveyor for the transport of the finished stone cubes to the take-off position or to feed packing systems which can be used with or without transport pallets. With the use of special profiles (U-profiles) an automatic vertical strapping without transport pallets is possible.

More individual solutions are of course possible, just contact us!

Hawk can integrate various

packing systems

in the field of cube transport, which protect the finished products safely and reliably. For later identification, the products can be identified through

labeling systems

.

more

Surface treatment

Due to the increased demand of individual concrete products, manufacturers are focusing more and more on surface finishing options. Special color accents, but also the design of optics and surfaces are becoming increasingly important.

Hawk supplies components for popular finishing techniques such as

washing

or

splitting

.

Aging or shot blasting or other surface treatment equipment

can be inserted into the process or used individually.

mehr

Remodeling

Due to different board sizes and stone layers within the manufacturing plants it is sometimes necessary, to increase or decrease the block layers in process direction. Therefore Hawk offers several ways to prepare the concrete blocks according to customer requirements suitable for transport.

For example, a Hawk shifter (in similar design as the

Hawk Cuboter

) is one method and pushing and separation tables are another example. Special versions are available on request. We will be happy to consult with you.

Powertainer

The Hawk Powertainer is really tough!: from the beginning the control cabinets are pre-installed on the right place. This protected and clean location offers optimal conditions for these components. In addition, a simple climate control is possible. The cable management system in the Powertainer ensures a EMC-suitable cabling and reduces malfunction. By possible occurences of malfunction, defauls within the Powertainer can be detected much more easily.

For the customer, a further advantage is clearly obvious: Hawk delivers the tried and tested concept of the closed electrical operating room too!

Hawk even goes a step further with the development of the "container concept..."

more

Control system and safety devices

Hawk's production systems are characterized by a high degree of automation resulting with a correspondingly high operatonal efficiency. In addition to the robust design of components, a customer-oriented operating concept is a key success factor in customer utilization of the Hawk system.

The

Hawk plant control software

(Hawk FAST Factory Automation Service Tools) is a modular software for uniform operation and visualization of the components. The key feature is that the plant is controlled through a single software resulting in an integrated, singular data concept across the entire plant operation.

The integrated operator guidance is based on well-known operating systems. The freely programmable visualization and scalable software can be adapted by Hawk to individual customer requirements. The software is expandable to customer requirements.

Learn more!

Plant specific and practical oriented

safety concepts

are developed by a multi-discipline team of experienced Hawk employees.

More details...

Hawk multi-functional block machine is designed to meet the mass and stable production of a variety of blocks by changing the different molds. This contains the production of bricks, pavers, hollow blocks, kerbstones etc. With humanized designed aviation plugs for connection and automatic control system, the machine is extremely easy to use for everybody

Hawk multi-functional block machine is designed to meet the mass and stable production of a variety of blocks by changing the different molds. This contains the production of bricks, pavers, hollow blocks, kerbstones etc. With humanized designed aviation plugs for connection and automatic control system, the machine is extremely easy to use for everybody

Selected by more than 95% customers, with success experiences for more than 1000 plants in more than 60 countries. Basic block making plant is the typical way to build a factory, with all standard parts.

Selected by more than 95% customers, with success experiences for more than 1000 plants in more than 60 countries. Basic block making plant is the typical way to build a factory, with all standard parts.

Standard products or tailor made? As you wish.

Standard products or tailor made? As you wish.