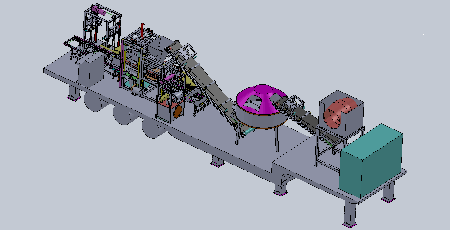

Raw material storage, dosing, and mixing

Sand lime bricks consist of the two raw materials sand and lime only. For the manufacturing process, water is required in addition. The raw materials that are mostly supplied from local extraction places are stored separately in raw material silos. On the way to the silos, the sand passes a screening station to separate oversize material.

Hawk sand lime brick making plants are designed to use at least two different types of sand. The advantage for the customers is that the product quality can directly be influenced by a specific mixture of the different types of sand.

The raw materials sand, lime, and water are exactly dosed and weighed in individual scales and fed into the intensive mixer. In the mixing process, a homogeneous and highly disperse sand lime compound is generated.

The complete automatic process is controlled and monitored via the Hawk mixing plant control system .

Hawk multi-functional block machine is designed to meet the mass and stable production of a variety of blocks by changing the different molds. This contains the production of bricks, pavers, hollow blocks, kerbstones etc. With humanized designed aviation plugs for connection and automatic control system, the machine is extremely easy to use for everybody

Hawk multi-functional block machine is designed to meet the mass and stable production of a variety of blocks by changing the different molds. This contains the production of bricks, pavers, hollow blocks, kerbstones etc. With humanized designed aviation plugs for connection and automatic control system, the machine is extremely easy to use for everybody

Selected by more than 95% customers, with success experiences for more than 1000 plants in more than 60 countries. Basic block making plant is the typical way to build a factory, with all standard parts.

Selected by more than 95% customers, with success experiences for more than 1000 plants in more than 60 countries. Basic block making plant is the typical way to build a factory, with all standard parts.

Standard products or tailor made? As you wish.

Standard products or tailor made? As you wish.