Some tips for your paver making 路面砖生产的小技巧

a. Base mix materials:

-Sands

-Crushed fine aggregates

-Aggregates

-Cement

-Water

b. Face mix materials

-Sands

-Cement

-Pigment

2. How you chose the material, and what is affects?

a. BASE MIX MATERIAL:

-Sands:

Type: River sand

Size:1-2.5mm

Functions: fillers,

Effect: ↓Viscosity, ↑compaction index, Fine texture

-Crushed fine aggregates:

Type: Similar to granite

Size:<5mm

Functions: middle size structural skeleton

Effect: ↑Viscosity, ↑compaction index

-Aggregates:

Type: Similar to granite

Size: ~10mm

Functions: Main skeleton, ↑ strength sharply

Effect: ↑Viscosity, ↓compaction index, coarse texture

-Cement

Type: OPC/Fly ash cement (>425)

Functions: Binder (C-S-H), Critical on strength

Effect: ↑Viscosity, ↑compaction index, sensitive to water

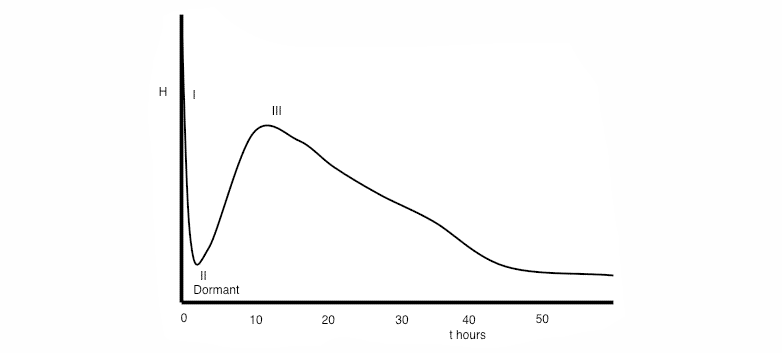

Phase III after 12Hr mixing time:

Cement with water<5mins

Mixture in the hopper<20mins

-Water:

Type: Tape water

Functions: Hydration with cement, lubrication

Effect: More ↑compaction index & ↑ Viscosity

Less ↓compaction index & ↓ Viscosity

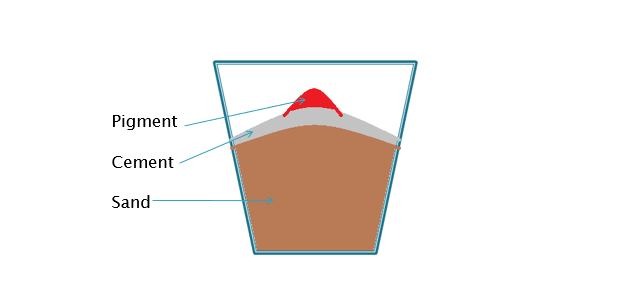

b. FACE MIX MATERIAL:

-Surface sands

Size<2mm

Type: River sand

-Cement

Type: White and grey cement

White cement: Color

-Pigment

Type: Iron oxide, CrOx

P.s.: Anti oxidizing agents & Anti UV

3. What you should notice during the mixing time?

a. Mixing method (in order)

-Aggregate mixing

-Dry Mixing (+ cement)

-Wet mixing (+water)

Note: Mixing time should be less than 5 mins after adding water.

Long mixing is not good for making the products.

Hawk multi-functional block machine is designed to meet the mass and stable production of a variety of blocks by changing the different molds. This contains the production of bricks, pavers, hollow blocks, kerbstones etc. With humanized designed aviation plugs for connection and automatic control system, the machine is extremely easy to use for everybody

Hawk multi-functional block machine is designed to meet the mass and stable production of a variety of blocks by changing the different molds. This contains the production of bricks, pavers, hollow blocks, kerbstones etc. With humanized designed aviation plugs for connection and automatic control system, the machine is extremely easy to use for everybody

Selected by more than 95% customers, with success experiences for more than 1000 plants in more than 60 countries. Basic block making plant is the typical way to build a factory, with all standard parts.

Selected by more than 95% customers, with success experiences for more than 1000 plants in more than 60 countries. Basic block making plant is the typical way to build a factory, with all standard parts.

Standard products or tailor made? As you wish.

Standard products or tailor made? As you wish.